3D printing technology with HP Multi Jet Fusion 5210 is currently the most advantageous in terms of speed and control of part properties. The Multi Jet Fusion (MJF) printer, is a powder bed 3D printing system, able to fuse the fusion and detail agents to the powder by binding them together.

It allows us to produce and create unique, more complex parts, maintaining excellent dimensional characteristics, mechanical properties and excellent surface finishes, at low costs and in a very short time.

The HP Multi Jet Fusion printer presents itself as the industrial system with the highest level of productivity in the world of additive manufacturing. Its main characteristics are undoubtedly: reliability, repeatability of parts, low production cost and new materials. Printing times and costs are therefore optimized for production and the workflow is simple, but with high levels of accuracy, thanks to constant production monitoring.

This printer introduces a novelty compared to the other machines, the Natural Cooling Unit, that is a removable printing unit that allows a continuous and more efficient production of the machine.

What is the printing process and how does it work?

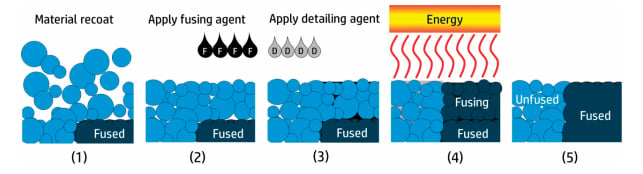

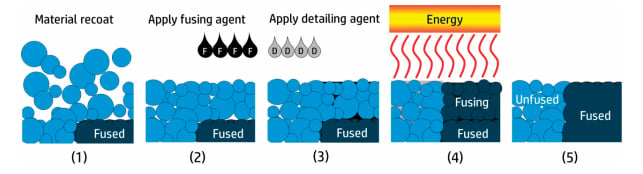

The HP 5210 MJF 3D printer starts by spreading thin layers of plastic dust on the work area. Subsequently, the carriage containing the printheads will pass over the powder bed, releasing drops of agents. The fusion agent through the energy of the lamps, at a temperature between 182 ° and 186 °, will melt in the section of the interested parts, while the detail agent will be deposited in the contour to block the fusion and optimize accuracy of the parties.

This process continues layer by layer until a finished and functional part is formed.

- The material is released over the entire work area.

- A fusing agent is selectively applied where the PA12 particles must fuse together.

- A detailing agent is selectively applied where the fusion action must be reduced or amplified.

- The part now consists of fused and unfused areas.

The whole is repeated until the complete part has been formed.

So what are the advantages of the Multi Jet Fusion 5210 printer?

Greater predictability of production

- Get high quality: precise details, sharp edges and textures, optimal performance at an industrial level OEE.

- Produce functional parts with best-in-class isotropy with the latest generation of HP Multi Jet Fusion systems.

- Reduce errors, failed jobs, and unexpected downtime.

Open up to more applications and markets

- Tackle multiple end-part applications with new levels of repeatable accuracy and best-in-class economy.

- Uses different types of materials (PP, PA11, PA12, PA12 GB)

- Address sustainability, with fewer parts of your carbon footprint

Open up to more applications and markets

- Better economy and productivity for production environments (over 160,000 cm3 per day)

- Simplified workflow, improved process development, optimized work efficiency and increased production efficiency

This is why the Niuo platform was designed: agile and intuitive to bring your dreams and ideas to life. Recover your idea in the drawer and try now a new type of experimentation: with the online estimator you know exactly costs and delivery times!