3D printing

Leggi di più

The pigmentation process in 3D printing

The pigmentation process in 3D printing allows to give an aesthetic improvement to the piece...

The development of 3D printing technologies has led to a real transformation of manufacturing by fostering a variety of sectors ranging from industry to the medical field.

In this mode of production, thermoplastic material passes through a heated nozzle to deposit it on a plate according to file directions. The Z-axis is built up layer by layer.

Value → economical

Limit → accuracy not high

A powder of thermoplastic material (e.g. Nylon PA12) is used. It is printed inside a printing booth, and by means of a laser the points indicated by the file are melted.

Benefit → rapid production time

Limit → rough finish on the surface

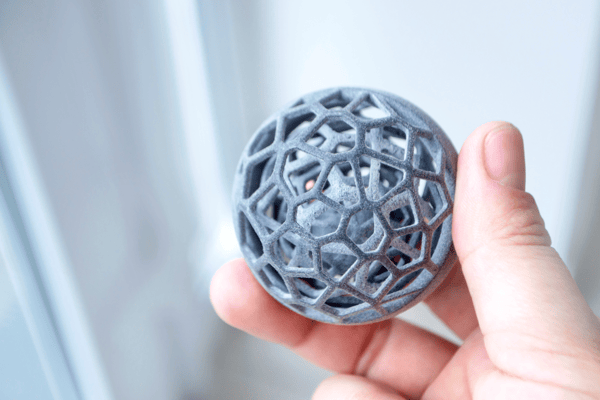

This is a powerful powder bed 3D printing technology using polymeric materials, such as Nylon PA12.

In this mode, unlike SLS, a patented inkjet printing technology is used: the printer colors the various points of the object black. Then halogen lamps bring the temperature up to 180° to fuse the dots, layer upon layer. Unmelted parts are discarded at a later stage, and, as with DPM printing, the powder not melted by the machine is reused for other prints.

Finally, parts printed in MJF can be post-processed by painting, sanding, and plating.

Why is HP Multi Jet Fusion the most advantageous technology on the market?

The pigmentation process in 3D printing allows to give an aesthetic improvement to the piece...